coriolis flow meter troubleshooting

By measuring Coriolis forces these flow meters reduce the need for fluid property correlations and auxiliary measurements. Accuracy linearity and repeatability.

Best Technology Guide To Coriolis Mass Flow Meter Sino Inst

Learn about the methodology for troubleshooting Coriolis Flowmeters by creating the correct problem statement to achieve resolution.

. Contact an Equilibar application engineer to help find the right back pressure regulator to improve the accuracy of the Coriolis flow meter in your application. Measures for Electrical Equipment for Measurement Control Regulation and Laboratory Procedures. Learn about the most common issues users face with regards to configuring and troubleshooting of Coriolis flow meters.

The devices can how ever be a source of danger if used incorrectly or for other. Oct 30 2000. These guidelines are designed to aid in troubleshooting and operation of provers that are in use together with Micro Motion Coriolis meters.

In actual work it is necessary to combine the specific characteristics of the actual product to carry out routine maintenance and troubleshooting. Maintains operation over a wide range of gas fractions and complex flow conditions EGM TM Standard pressure rating up to 300 bar 4351 psi. Check the output wires connection according to the wiring diagrams in Appendix.

A comparably sized Coriolis meter can run upwards of 9000 or more. What can I do for you. Coriolis Flow Meter Troubleshooting If no leaks are present bring the system up to the operating pressure.

It allows for measuring various fluids eg. Performance of Coriolis Flowmeter Day 2 1. This is causing the density and hence the flowrate to be erratic.

Coriolis Flow Meter Troubleshooting If no leaks are present bring the system up to the operating pressure. For halting flow through the sensor with a single valve install the valve downstream from the sensor. If none of the troubleshooting questions or.

Proline Promass 83 EndressHauser 3. Check all possible problems and causes before dis-assembling flow meter. Density Viscosity Measurement.

Coriolis Mass Flow Measuring System 6. These parameters are evaluated after the flow meter installation to determine its performance status and as part of a. A business unit of Emerson Process Management.

The meter will still function above 100 but this indication means. DN15 1 2. Proving results may vary if unstable.

Wrong connection of the output wires to the coriolis gas flow meter or secondary devices. Problem Cause Solution No flow volume displayed at monitor-ing unit. Karman vortex models the slurry may cause axial wear and clogging.

Coriolis mass flowmeter for low flow and dosing applications. Coriolis flow meters can calculate actual volumetric flow rate from the independently measured mass flow rate and density using the equation below where Q is the volumetric flow rate and r is the fluid density. Blending and Pigging Solutions.

Checking or repairing flow meter. High accuracy 01 for gases and liquids 03 kgh 001 lbmin. He has more than 30 years of experience in the Coriolis market ranging from engineering applications and sales and marketing.

Q m r. The first barrier to Coriolis world domination can be summed up in a single word. Tom OBanion is the director of industry differentiation at Micro Motion Inc.

The Unit has been calibrated and is operational. Planning Installation Manual October 2021 20002158. Proline Promass 83 2 EndressHauser.

Coriolis Flow Meter Troubleshooting - manufacturer factory supplier from China Total 24 Products for Coriolis Flow Meter Troubleshooting 100mm Coriolis Mass Flow. Flow volume is too low to measure Increase flow volume. As an industry leader in Coriolis meter research testing and systems SwRI.

If the sensor is installed in a vertical pipeline liquids and slurries should flow upward through the sensor. I am looking for ideas on how to minimize the fluctations in. Any drive gain value below 100 means that the flow tube vibration in the Coriolis meter is still at the precise target amplitude distance apart at the peak of cycle.

For flow meters that obstruct flow ie. With an electromagnetic type flow meter wear and clogging are minimal due to the free-flowing structure of the unit. Three primary parameters include in order.

Most other flow meter technologies produce volumetric flow as the raw output which is typically converted into a standard volume. Our problem is we have air bubbles entrained in the liquid. Cdcosta Chemical OP 27 Nov 03 1252.

Coriolis Mass Flow Meter Troubleshooting Manufacture and Supplier in China. Dirty little secret no. Verification can be applied in flow meter or process troubleshooting.

When choosing a flow meter for any application some performance parameters are more critical than others to determining which meter will work best in an application. We have installed a Coriolis mass flow meter on a 2 process line. Gases should flow downward.

In the process of daily use the fluid measurement should be carried out in strict accordance with the working temperature pressure and flow range specified by the Coriolis mass flowmeter and should not be exceeded. Fluid is not flowing See Problem. When using coriolis mass flow meters to measure liquids flow with entrained air especially viscous liquids the meter reports inaccurate readings.

Entrained air requires additional energy to drive the meter tube as the entrained air absorbs some of the energy. Learn about the methodology for troubleshooting coriolis flowmeters by. This means you can trust the mass flow measurement as long as the drive gain is any number less than 100.

For those who have evaluated Coriolis meters in the past this. The Unit has been calibrated and is operational. Micro Motion ELITE flow meters are high- precision Coriolis flow meters that are often used in the oil and gas industry in conjunction with volume provers.

The problem is reportedly related to the meter drive coil running out of energy. Check the computers port used to connect the flowmeter to the computer through digital interface. While these unique features make Coriolis flow meters attractive natural gas operators often need assistance with installation configuration and operations and maintenance.

The Promass 83 flow measuring system. Keep the sensor tubes full of process fluid. Also thread and clamp connections.

Entrained air requires additional energy to drive the meter tube as the entrained air absorbs some of the energy. Back Pressure Regulators can be used to prevent bubble formation in Coriolis flow meters. Fluid is not flowing below.

A one-inch line magnetic flow meter and transmitter for example can be had for 3000 or less.

China Dn32 Type 0 1 Grade Industrial Liquid Coriolis Mass Flow Meter China Coriolis Mass Flowmeter Coriolis Flow Meter

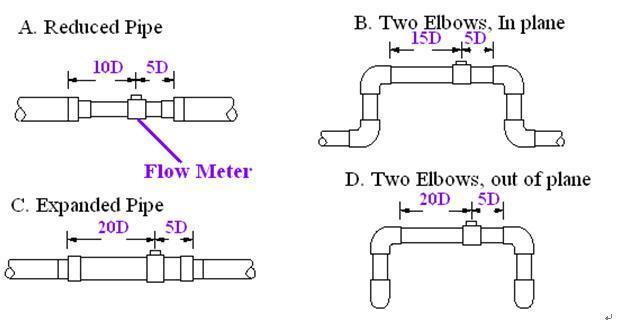

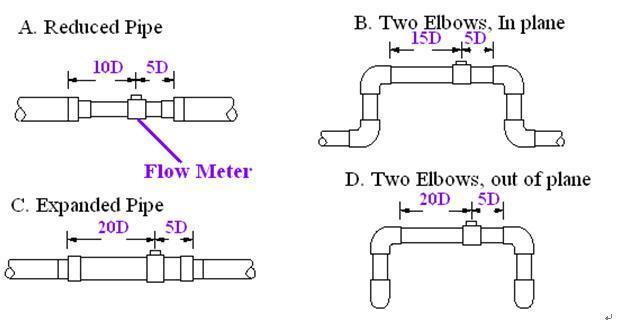

Mass Flow Meters Installation Guidelines Rms Engineering

How To Zero A Coriolis Meter Using The 5700 Transmitter Display And Prolink Youtube

Rotamass 3 Series Coriolis Mass Flow Meter Yokogawa Electric Corporation

Pemasangan Sensor Mass Flow Meter Coriolis Silver Automation Instruments Ltd

Rota I Mass I Total Insight Pt Yokogawa Indonesia

Coriolis Mass Flow Meter From China Manufacturer Q T Instrument Co Ltd

Slw Liquid Turbine Flow Meter Installation

Rota I Mass I Total Insight Pt Yokogawa Indonesia

Sets Of Comparison Transfer Flowmeters Combination Of A Coriolis And A Download Scientific Diagram

Micro Motion Coriolis Meter Characterization And Configuration Using Prolink Youtube

Testing Coriolis Meters With Pd Vane Pumps Sciencedirect

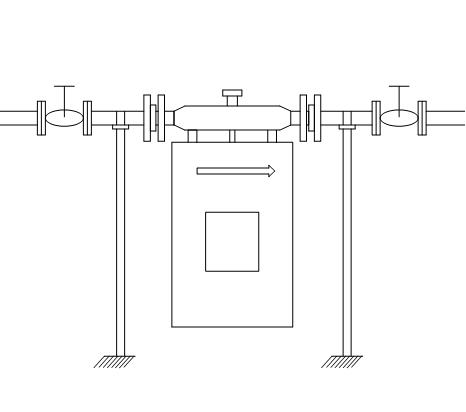

How To Install A Coriolis Flow Meter

Coriolis Mass Flow Meter The Piping Engineering World

Accuracy And Ease Of Installation The Benefits Of Coriolis Flow Meters

Calibration Certification And Re Certification Of Coriolis Flow Meters Youtube

Coriolis Flowmeter 1 Basis 2 Housing 3 Tube 4 Drive Coil 5 Download Scientific Diagram